Here s an example calculation using the compressed air pipe sizing table table 1 and the equivalent pipe length table table 2.

Compressed air system design calculations pdf.

Let s say we have a rotary screw compressor of 30 kw that can supply 250 nm3 hour normal cubic meters per hour.

Plant air compressor systems can vary in size from a small unit of 5 horsepower hp to huge systems with more than 50 000 hp.

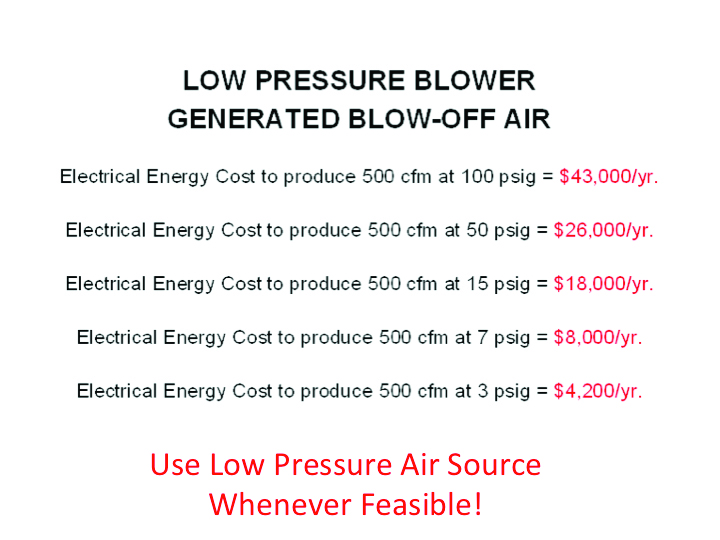

In many industrial facilities air compressors use more electricity than any other type of equipment.

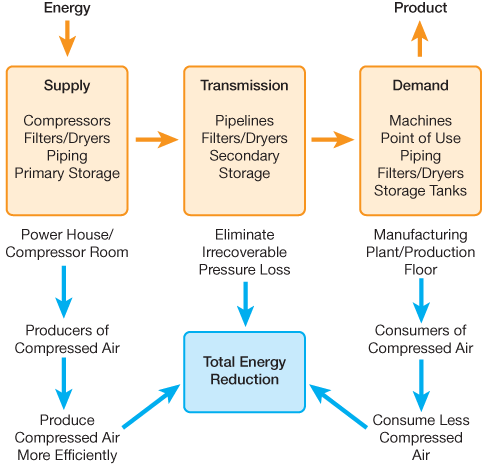

Any business seeking to make operations more sustainable should take steps to fully understand the compressed air system calculate its true cost and implement.

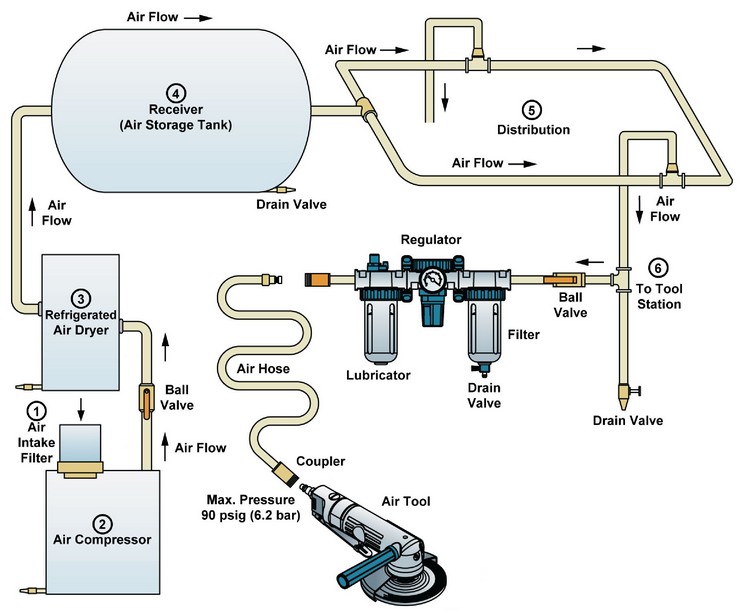

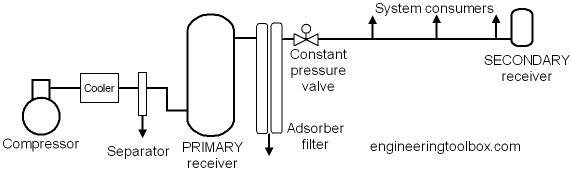

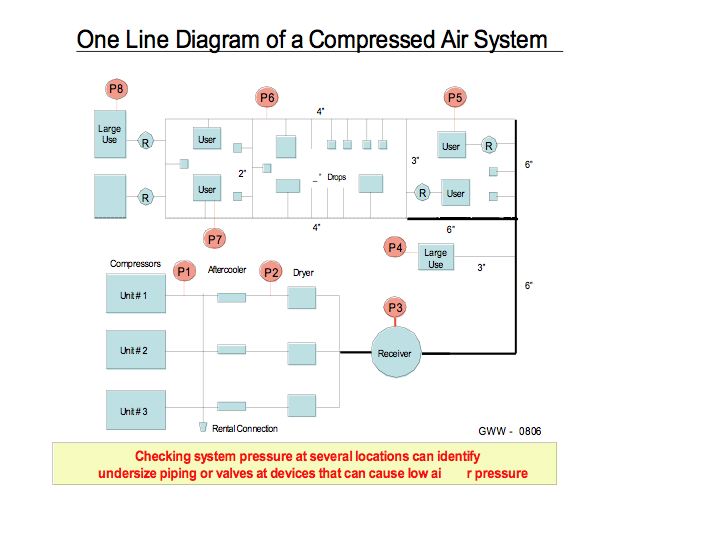

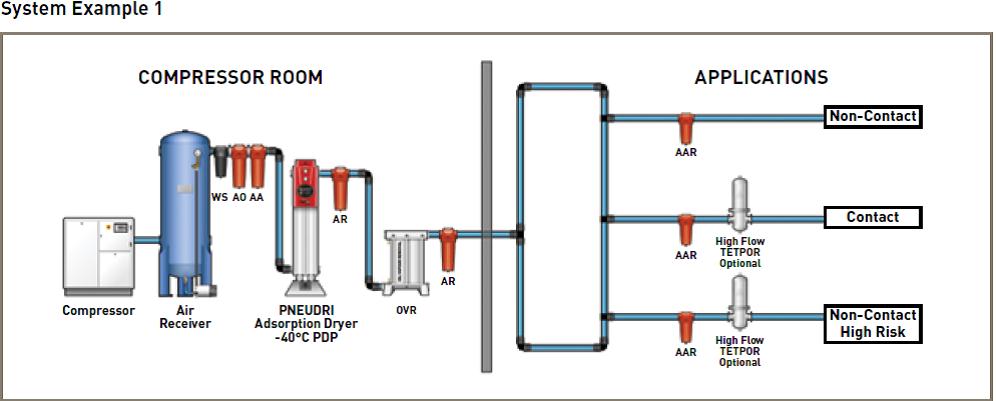

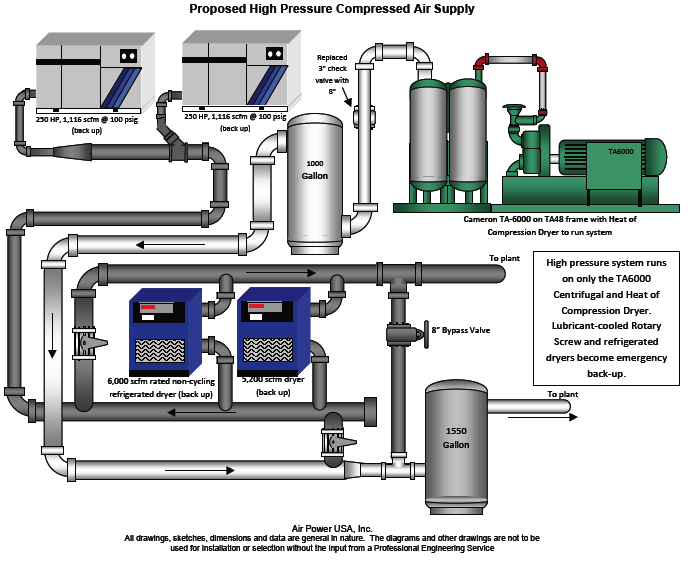

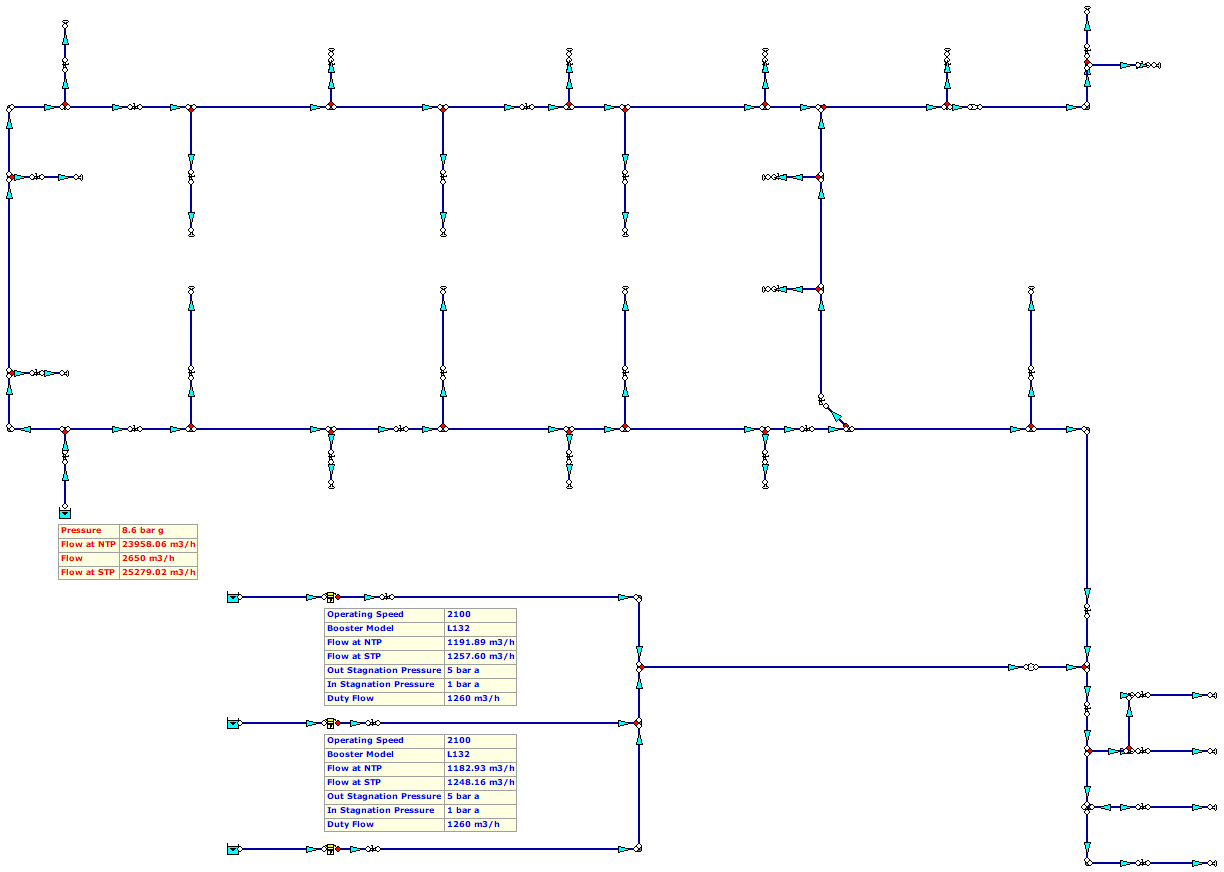

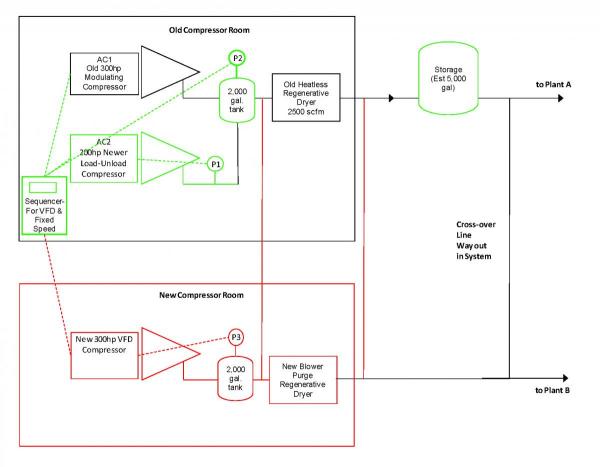

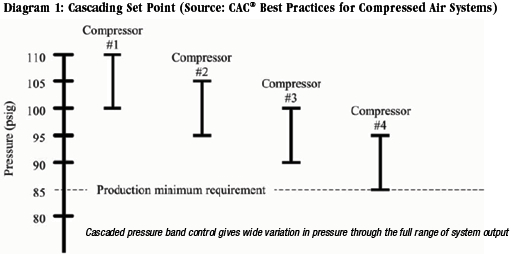

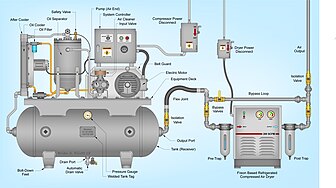

A systems approach entails looking at the entire com pressed air system from start to finish when considering optimization.

Taking a systems approach can help you devise solutions to these challenges.

2 purpose of this reference guide.

Take a systems approach to compressed air we have clearly established that compressed air systems are inefficient expensive and often misused.

It is not a design guide for new or expanded air compressor systems.

Readers are cautioned to use proper health safety and.

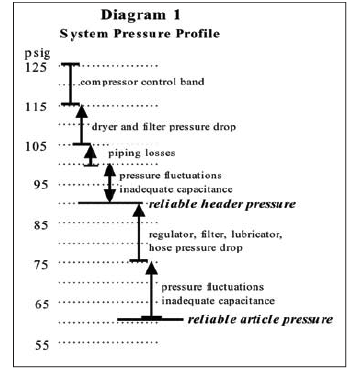

Compressed air systems often operate inefficiently using an unnecessary and expensive amount of energy.

In many cases the compressed air system is so vital that the facility cannot operate without it.

The compressed air pipe routing design and dimensions are important factors for the efficiency reliability and cost of compressed air production.

Occasionally a large pressure drop in the piping system is compensated by adjusting or increasing the working pressure of the compressor from for example 7 bar to 8 bar.

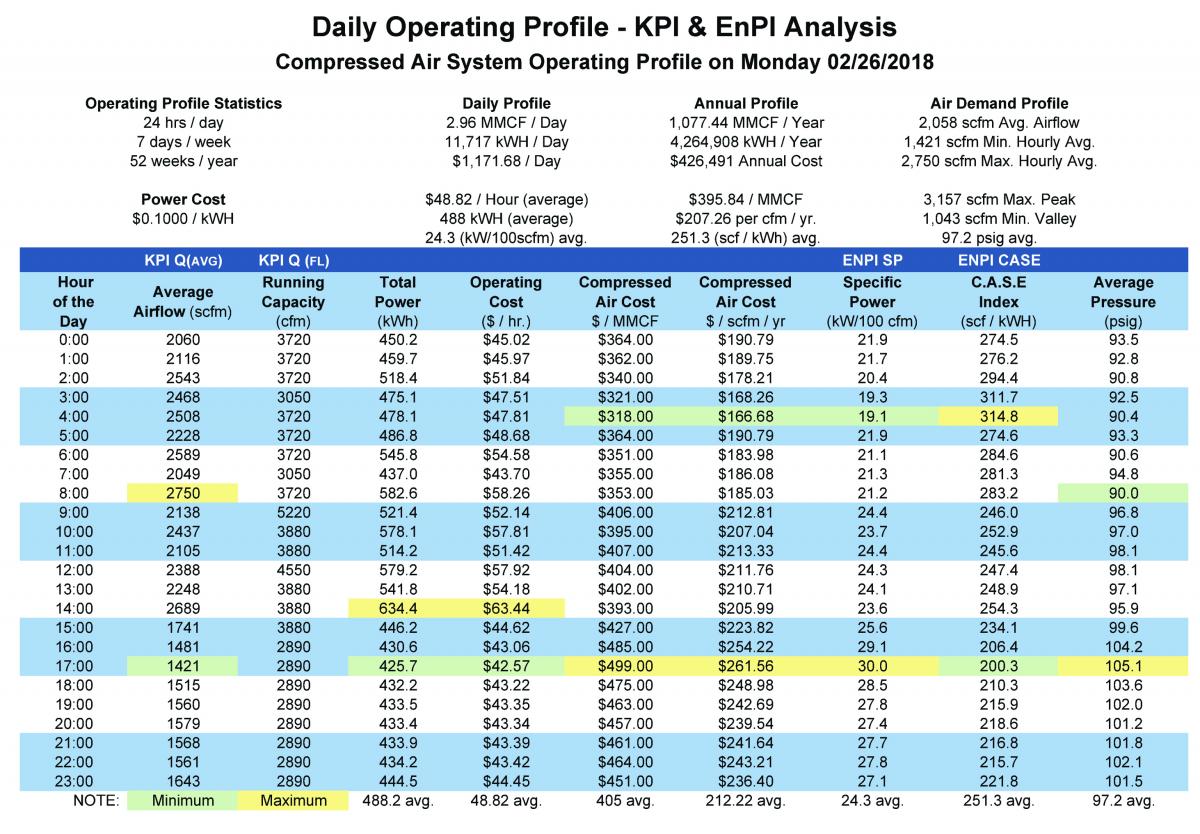

Analyzing and optimizing compressed air systems.