Common uses of compressed air the ispe good practice guide asserts that a logical method for determining the requirements of a facility s compressed air quality is to review the role of the gas in the process.

Compressed air piping spec.

Piping shall be protected as specified in.

Black iron schedule 40 piping in compressed air systems is commonly used due to price and durability.

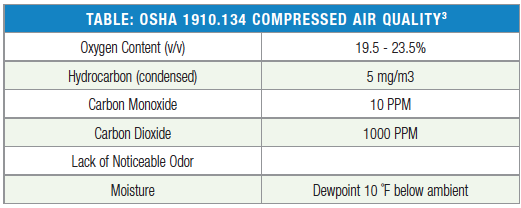

Iso 8573 1 2010 compressed air specifications.

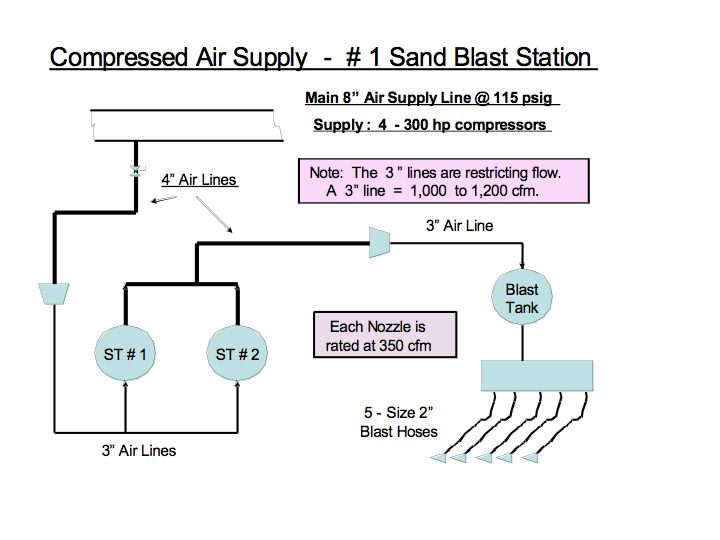

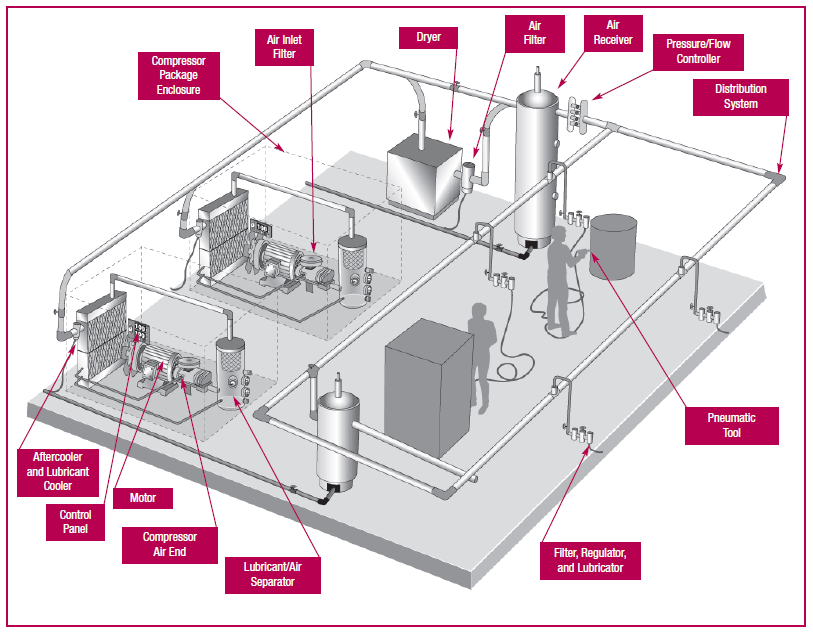

The purpose of compressed air piping systems is simple.

While some facilities use compressed air in direct contact with products to clean.

Underground air piping shall be type k soft drawn copper and shall not have any fittings installed in concealed locations.

Many of our customers have established their own criteria by monitoring the performance of the system over a given time period reviewing literature specifications evaluating equipment.

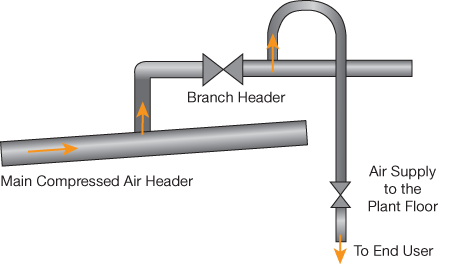

Pipe diameters of 3 and below are normally threaded while larger diameter headers use welds and flanges.

Ispe good practice guide compressed air specifications.

All factors considered aluminum is the premier choice for compressed air piping.

Many of our customers have established their own criteria by monitoring the performance of the system over a given time period reviewing literature specifications evaluating equipment.

The light weight of aluminum makes it easy to handle and install especially with push together connectors.

Operating temperature at 4 f to 176 f.

All pipe work shall be in conformity with the requirements of the applicable drawings and specifications.

It is non corrosive and remains leak free unlike black pipe systems.

To deliver compressed air to where it is needed.

Handing over of complete compressed air pipeline work.

Trace analytics llc specializes in the analysis of thousands of compressed air gas samples each year.

All compressed air piping above grade shall be schedule 40 galvanized steel pipe conforming to astm a 120 and ansi b36 20.

Aluminum is light weight making it easy to handle compared to schedule 40 or 80 pipe and is highly recommended for clean air applications.

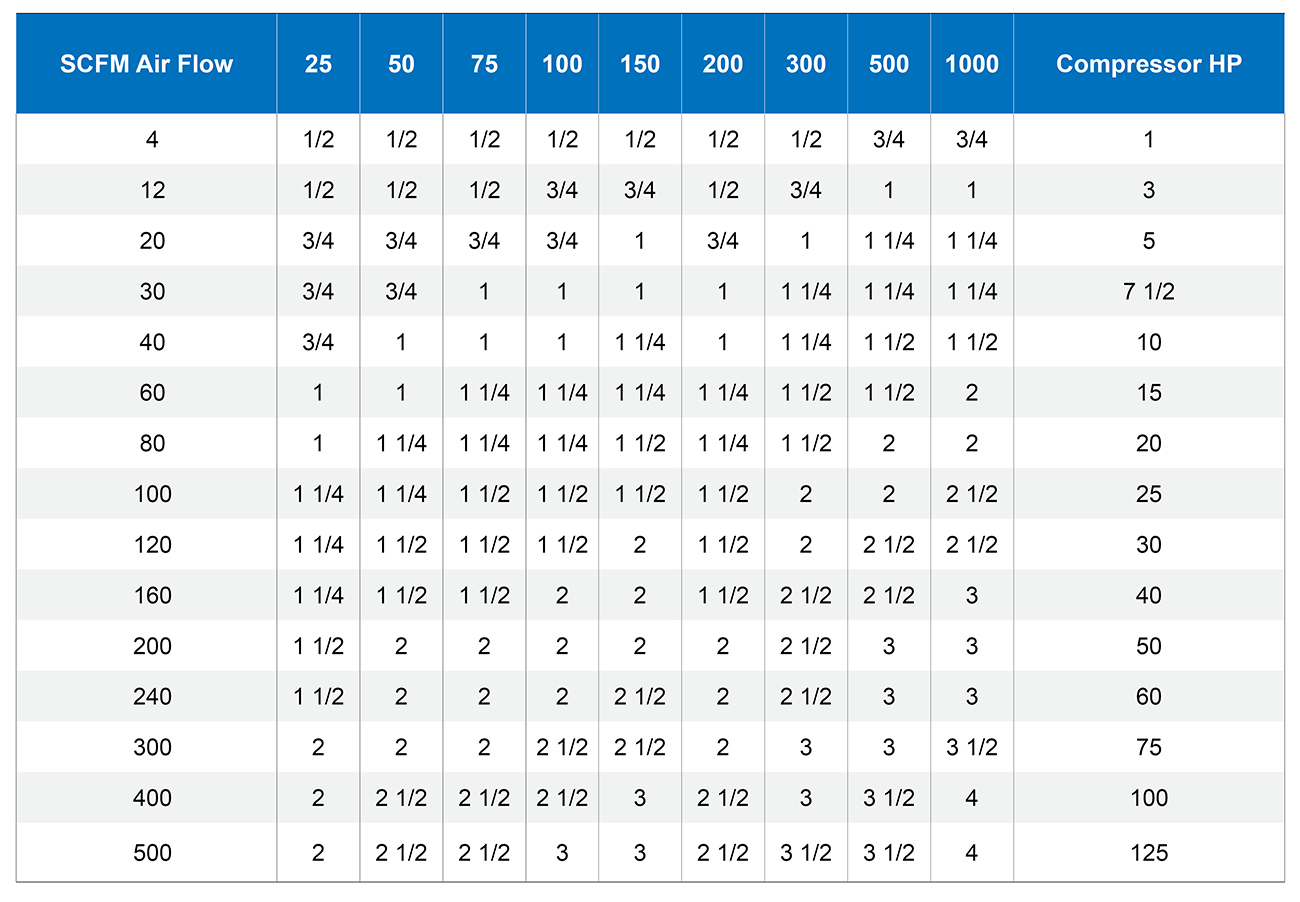

However designing a compressed air system is more difficult than you might imagine the compressed air has to be delivered with sufficient volume good enough quality and enough pressure to power the components that require compressed air.

2 1 compressed air pipe and fittings.

The latest technology are push to connect aluminum piping systems for compressed air lines such as parker transair.

Process gases and compressed air are used in a variety of ways depending on the product manufactured.

Aluminum piping does not corrode and it s leak resistant.

Trace analytics llc specializes in the analysis of thousands of compressed air gas samples each year.